Tap Drill Chart Business Mentor

FREE 8+ Sample Tap Drill Chart Templates in PDF

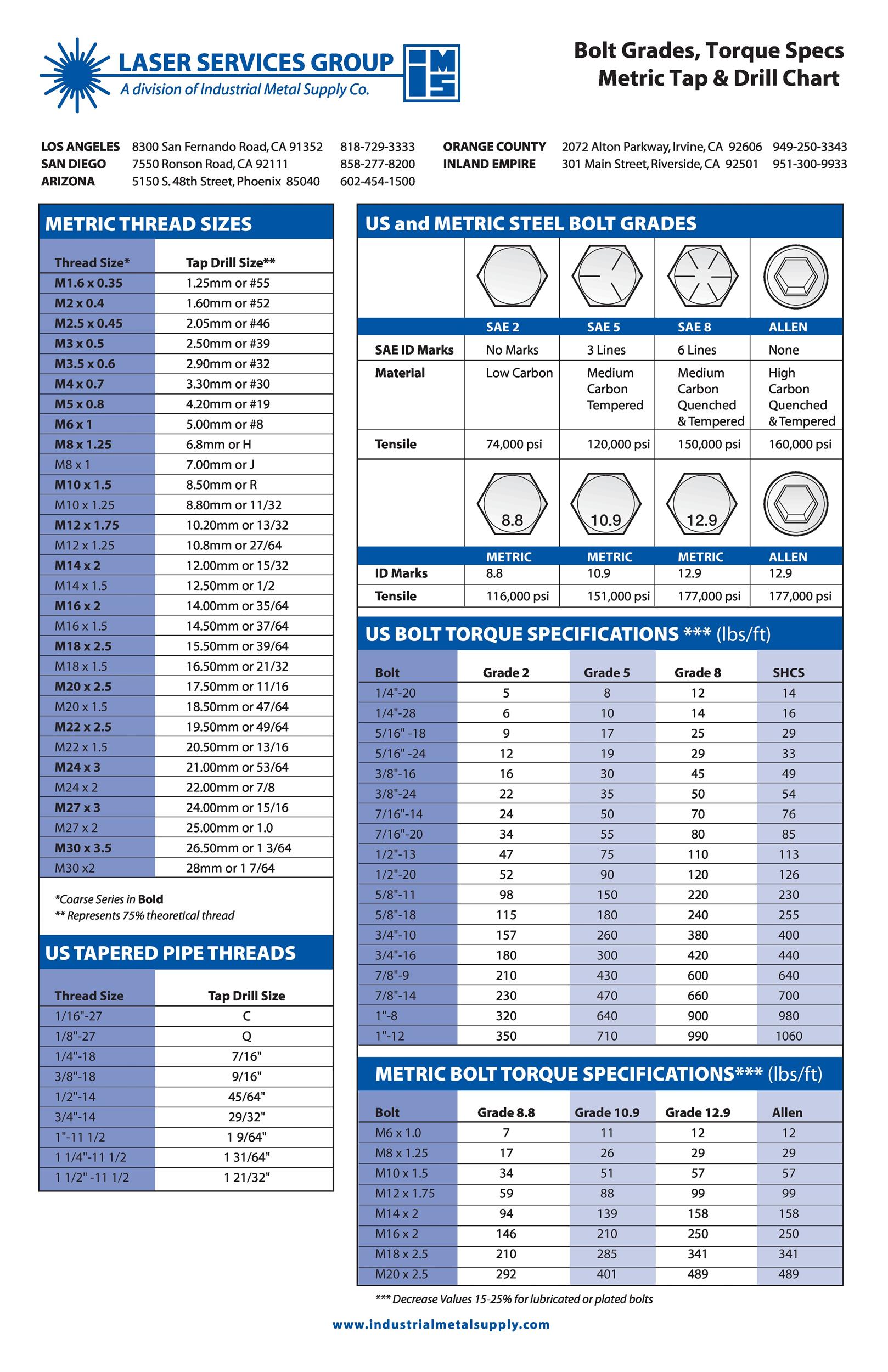

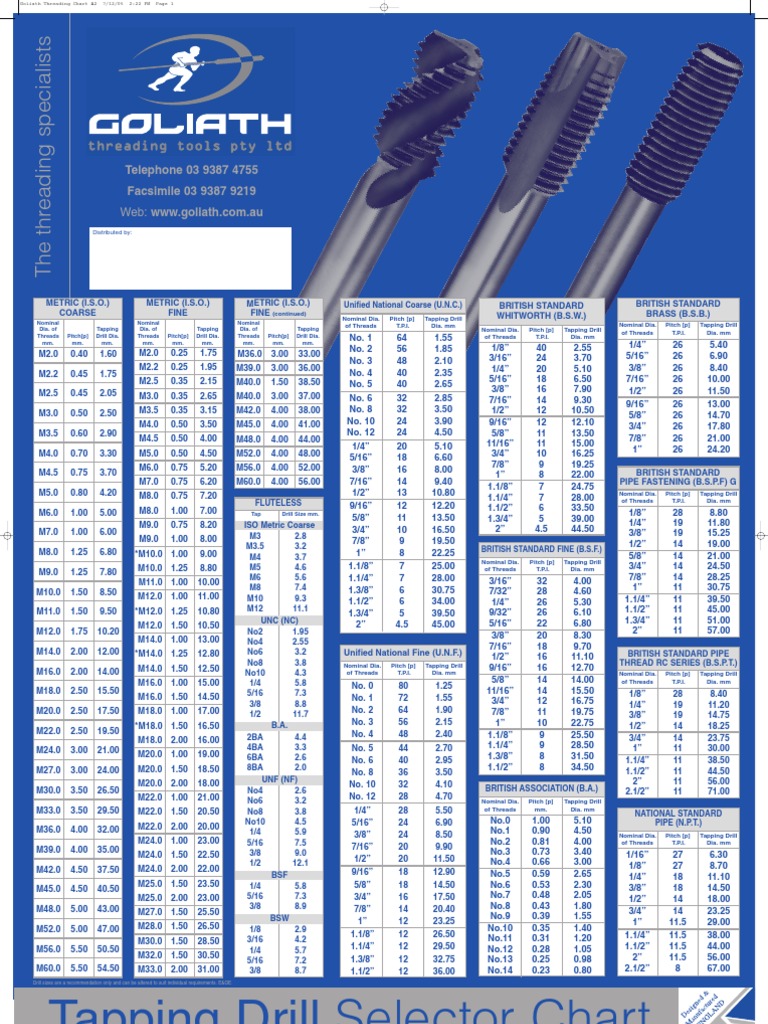

A tap drill chart determines what size hole to drill before tapping female threads and what size pipe is needed for male threads. Before starting to cut threads, there are a few factors to know to guarantee correct cutting: Unified or metric: Screw sizes come in two classifications: unified and metric. Unified is used mainly in North America.

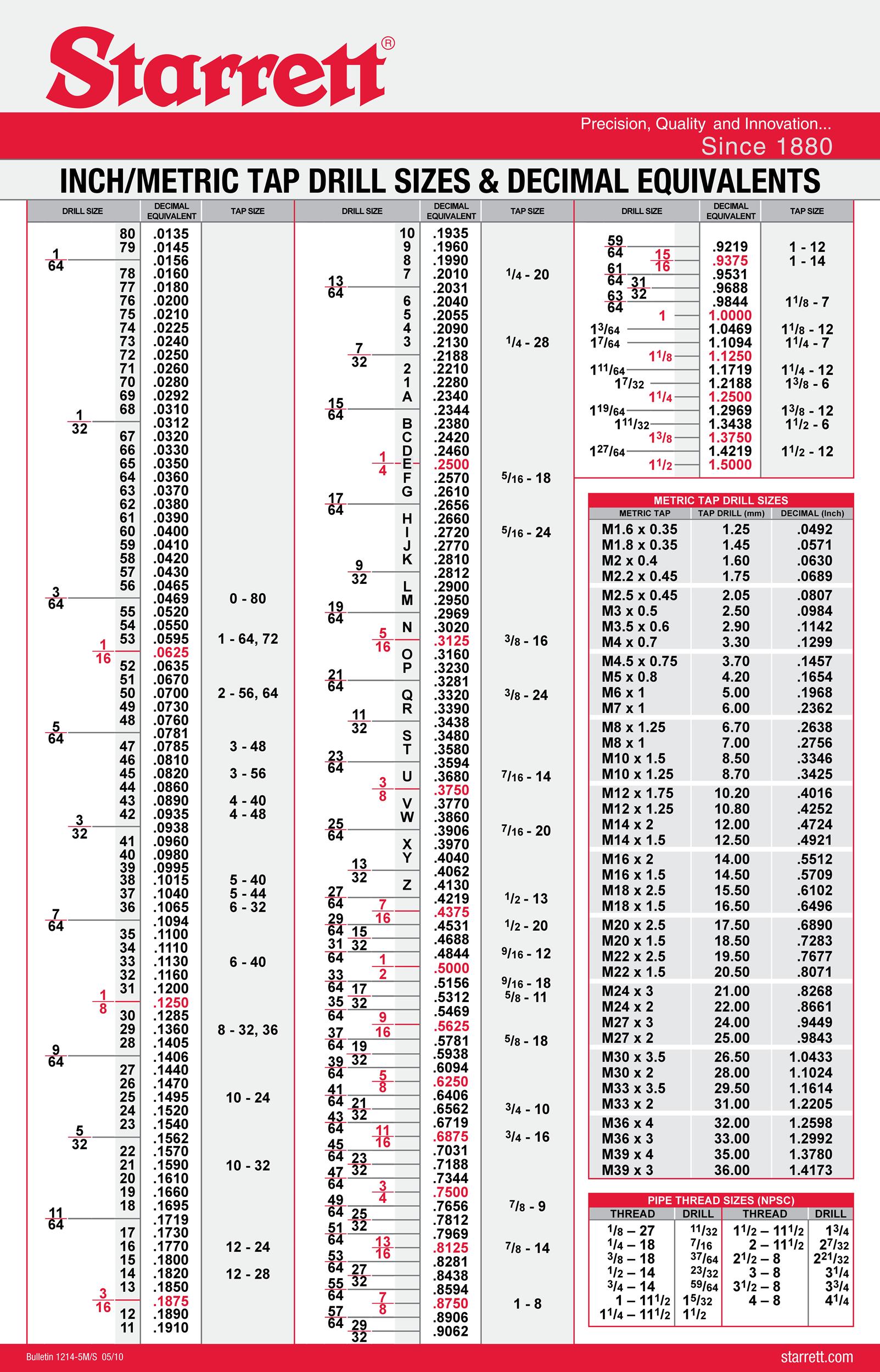

Buy Inch Metric Tap Drill Sizes & Decimal Equivalents Drill Chart for CNC Shop Garage

Plus, this exclusive tap & drill size chart includes valuable tapping speed recommendations, tap tolerances, tap standards and tap dimensions. Utilize this chart and increase the efficiency of your threading and machining applications. This comprehensive tap and drill chart was created in partnership with Nachi America Inc.

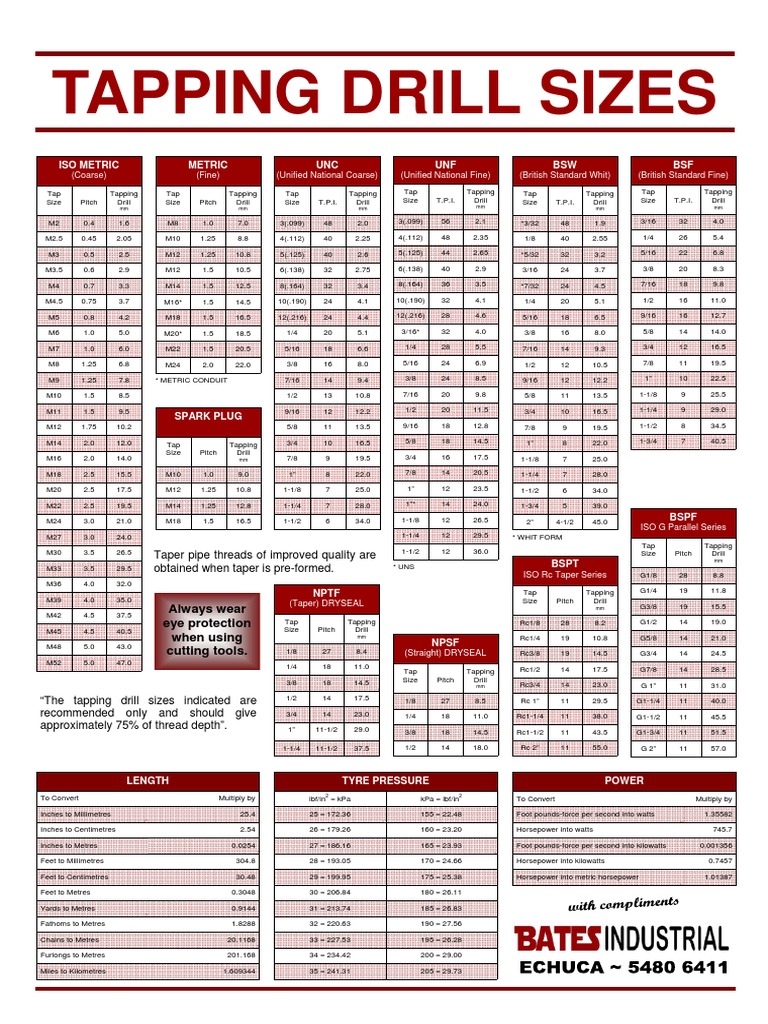

Tapping Drill Chart.pdf Units Of Measurement Length

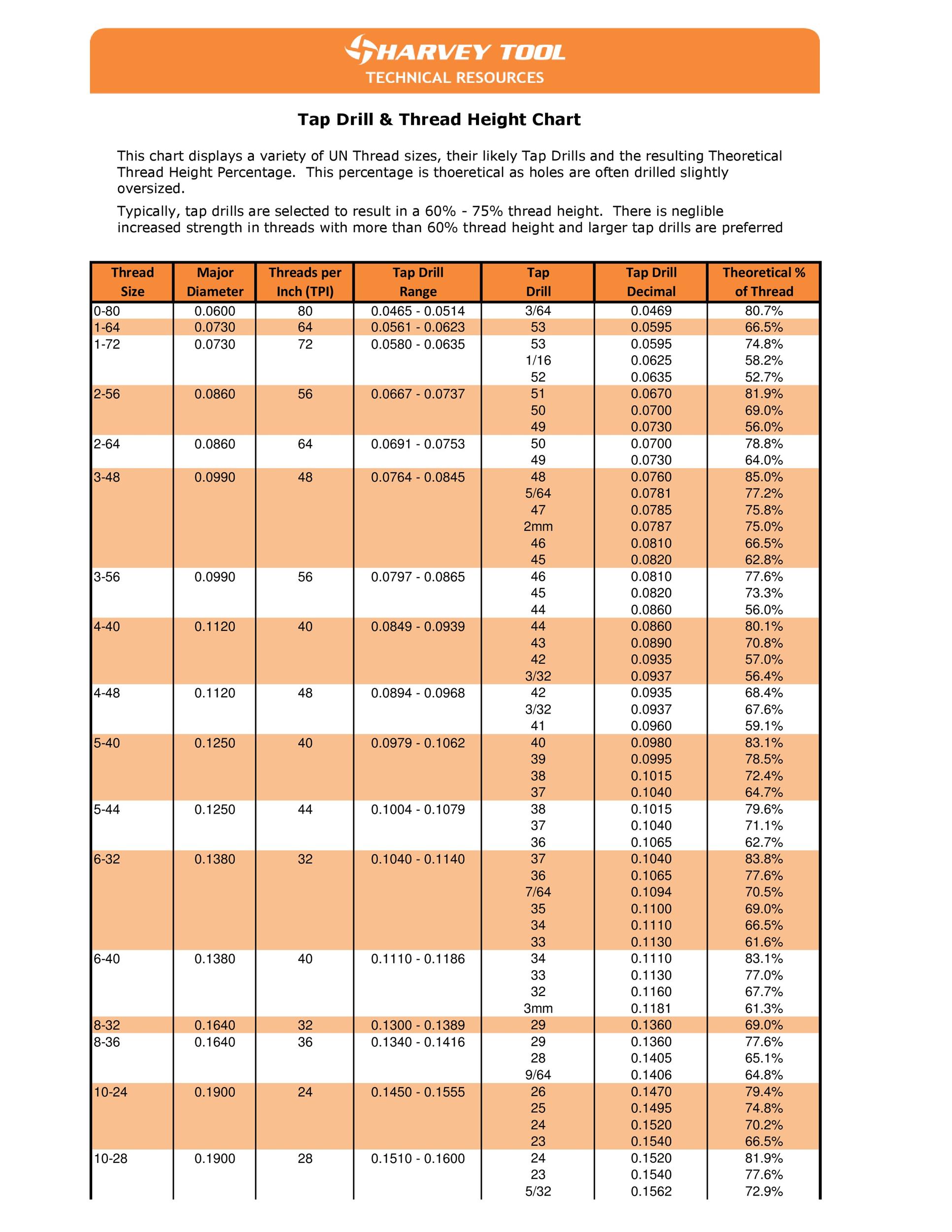

Tap Drill Chart. The most common way to produce an internal female thread is to drill a hole smaller than the major diameter and then use a tap to produce the thread. This is usually referred to as a tapping drill for the size of the thread that needs to be produced. A good way to decide on what diameter drill to choose is to use a tap drill.

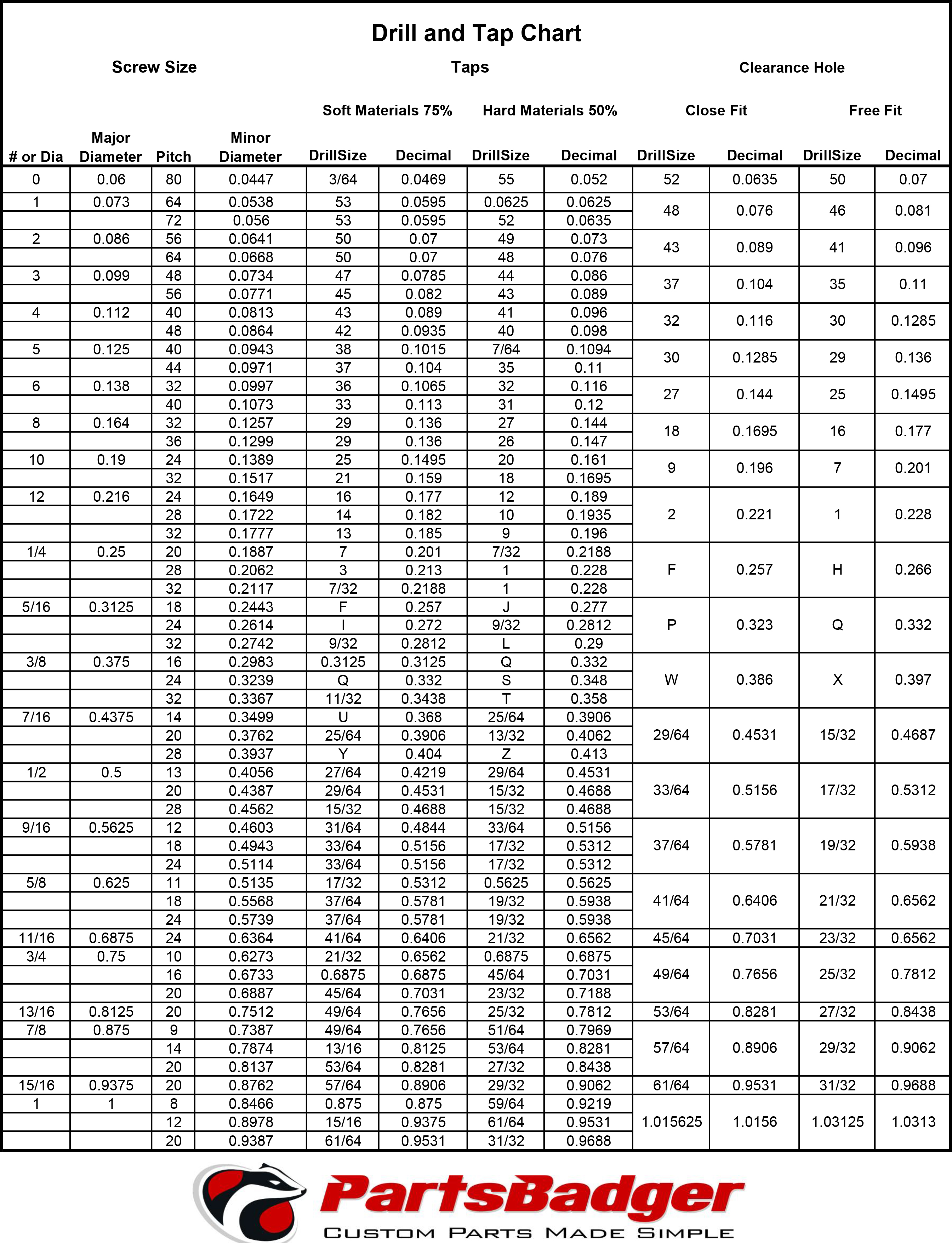

Drill and Tap Reference Guide by PartsBadger

Tap size Drilling chart The tap size chart provides a list of standard size taps, specifying the diameter and thread spacing, for fractional, metric, and screw sizes. The decimal equivalents of the diameters are shown in both English and Metric units. Fractional sizes are listed in inches, while metric sizes are listed in millimeters

Standard tap drill size chart tnden

For Metric threads, you can calculate the tapping drill by subtracting the pitch from the diameter of the thread. Here is an example, for an M5x0. 75 thread the tapping drill is 5-0.75mm = 4.25mm. For Imperial (inch) threads the tapping drill size is calculated in the same way, diameter minus pitch.

Metric Tap Drill Chart Free Download

A good tap drill chart like theprintable PDF versionbelow typically has three main columns or sections. The first column lists the standard drill sizes as a number (a fraction or letter drill size, for instance). The second column will list the inch decimal equivalent of the drill diameter of the the tap drill you need to use.

23 Printable Tap Drill Charts [PDF] Template Lab

Drilling and tapping. Creating a threaded hole is one of the most common machine shop tasks. There are two basic steps to the process - drilling the hole with the correct drill bit size and then threading or "tapping" the hole. Each step requires precise measurements. Drill a hole too large, and your screw, bolt, or pipe thread will be.

Free Printable Tap Drill Size Chart [PDF] Metric, Inch, NPT

Tap Drill Chart Drill sizes given are the 'closest' drill size. TAP SIZE CUTTING TAPS TRU-FLO ™ FORMING TAPS INCH METRIC DRILL SIZE DECIMAL EQUIVALENT DRILL SIZE DECIMAL EQUIVALENT 0-80 3/64 .0469 54 .0550 M1.6 X 0.35 1.25mm .0492 1.45mm .0571 M1.8 X 0.35 1.45mm .0571 1.65mm .0650.

Buy Inch Metric Tap Drill Sizes and Decimal Equivalents Chart for Garage CNC Shop

M4-07 we use the 3.3 mm tap drill. M4-05 we use the 3.5 mm drill. M4-035 we use the 3.6 mm drill bit. As per the ISO metric screw thread standard, the thread depth should be 0.614 x pitch, which is why a smaller pitch number also results in a lower thread depth value. Now engineers can sit down and manually calculate the right tap drill.

Unf Tap Drill Size Chart Pdf

List of Drill and Tap Sizes. Drill Bit Sizes (Metric) The drill size chart contains tools up to 1.5 inches in diameter, but larger tools are also commonly used. Drill Bit Sizes (English) Tap Sizes (Metric) For each thread count, the equivalent thread pitch is provided and for metric taps, the approximate thread count is shown based on the pitch.

23 Printable Tap Drill Charts [PDF] ᐅ TemplateLab

Create a fresh thread inside a hole by first re-drilling the existing hole. Look to the tap and drill chart for the correct size and start drilling. Next, position the square of the tap on top of the holder and tighten it. After that place the tip of tap inside the hole, make sure the tap is positioned in a perpendicular direction to the hole.

Drilling and Tapping Tips Drill bit sizes, Tap chart, Drill

20. .9387. 61/64. .9531. 31/32. .9688. This tap and clearance drill chart shows tap and clearance drill sizes for standard threads. There is also a printable version that has both metric and inch threads.

FREE 8+ Sample Tap Drill Chart Templates in PDF

The tap size chart provides a list of standard size taps, specifying the diameter and thread spacing, for fractional, metric, and screw sizes. The decimal equivalents of the diameters are shown in both English and Metric units. Fractional sizes are listed in inches, while metric sizes are listed in millimeters following the letter "M".

Tap Drill Chart 14+ Download Free Documents in PDF, Excel

A larger Thread height means a smaller tap drill size. A smaller Thread height means a larger tap drill size. Why Is it important? Since the feed always equals the thread pitch and the entire thread depth is machined in one pass by definition, these factors are not in our control. The thread depth is a primary factor (Next to the cutting speed) influencing a tapping tool's torque and tool life.

23 Printable Tap Drill Charts [PDF] ᐅ TemplateLab

UNC tapping drill size chart. A good rule of thumb to select a tapping drill for an imperial screw thread is 85% of major thread diameter for a coarse thread and 90% of major thread diameter for a fine thread. Note that this is for threads with a major diameter under 1". Over this size, the ratio changes and it is better practice to use a.

Standard Holes and Tapping Chart Machining Cutting Tools Free 30day Trial Scribd

Schematic of a machine tap. Below is a comprehensive drill and tap size chart for all drills and taps, imperial and metric, up to 36.5 millimetres (1.44 in) in diameter.. In manufactured parts, holes with female screw threads are often needed; they accept male screws to facilitate the building and fastening of a finished assembly. One of the most common ways to produce such threaded holes is.